AI in Manufacturing & Supply Chains: From Design to Delivery

Manufacturing is undergoing one of its biggest shifts in decades. AI in manufacturing is no longer a lab experiment – it’s becoming the backbone of how factories and supply chains operate every day. From predictive maintenance that keeps machines running to AI in supply chain management that ensures products arrive on time, companies are seeing real and measurable gains.

The momentum is only growing. The global AI in manufacturing market was valued at $8.14 billion in 2019 and is projected to soar to $695.16 billion by 2032, growing at a remarkable CAGR of 37.7%. Behind those numbers are practical wins: digital twins in manufacturing that mirror entire production lines, AI for predictive maintenance that cuts downtime, and AI in production optimization that reduces waste while boosting throughput.

Faced with rising complexity, unpredictable disturbances, and increasing customer demands, traditional methods can no longer keep pace. AI is stepping in to streamline processes, unlock insights, and enable real-time decision-making – transforming both production floors and global logistics.

Early adopters are already reporting improvements in output, quality, and resilience. In this blog, we will explore how manufacturing AI development is delivering these results today, and why investing now can set the foundation for long-term advantage. Let’s dive in!

Why AI Matters in Manufacturing & Supply Chains?

Manufacturing and supply chains are under more pressure than ever – volatile markets, shifting tariffs, and rising customer expectations leave little room for inefficiency. AI is emerging as the critical differentiator by delivering flexibility, accuracy, and speed that traditional automation simply can’t match.

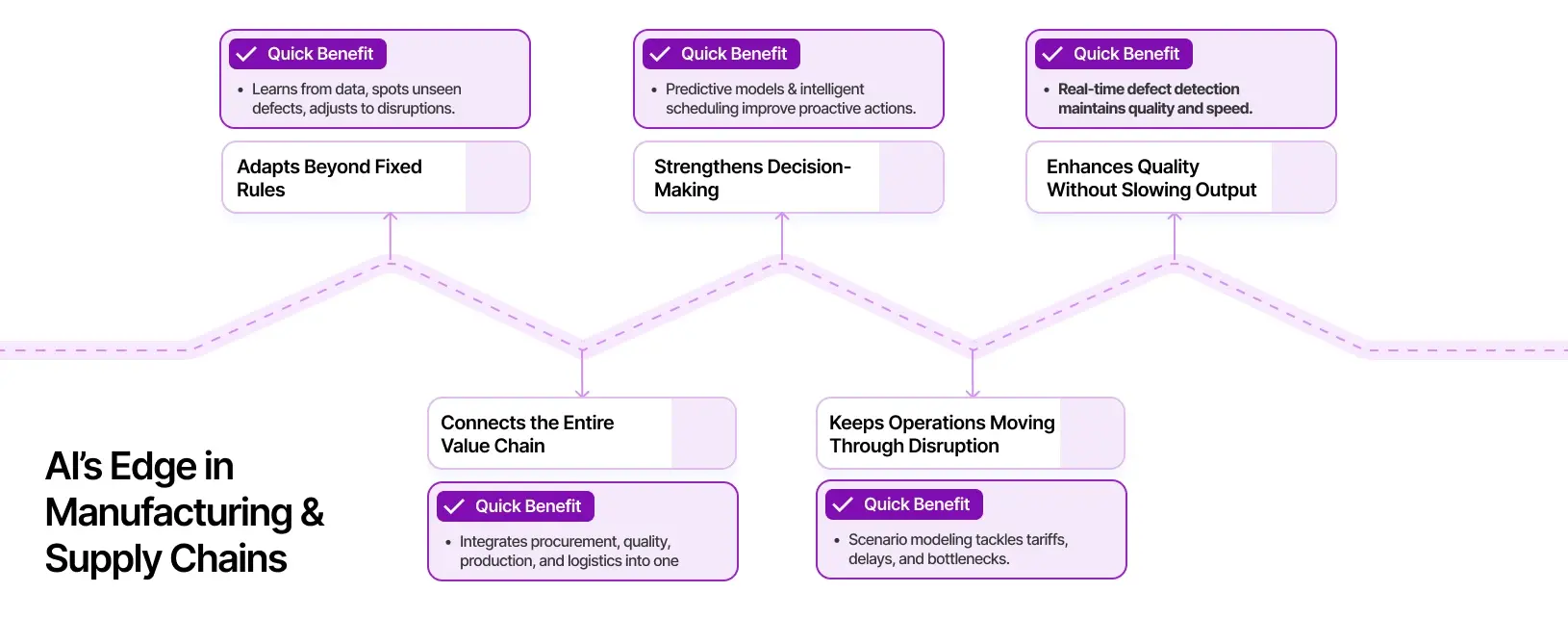

1. Adapts Beyond Fixed Rules

Unlike conventional automation, AI learns from data and adjusts to new conditions. Hence, spotting previously unseen defects or rebalancing supply plans when issues occur.

2. Connects the Entire Value Chain

By integrating procurement, quality control, production, and logistics data, AI provides a unified view of operations. Further, turning complex and scattered information into clear and actionable insights.

3. Strengthens Decision-Making

Predictive models handle maintenance needs, while intelligent scheduling tools align production capacity with market demand. This further enables proactive rather than reactive responses.

4. Keeps Operations Moving Through Disruption

AI-powered scenario modeling helps manufacturers handle tariff shifts, shipping delays, or supply bottlenecks without bringing production to a halt.

5. Enhances Quality Without Slowing Output

Computer vision and machine learning detect flaws in real time. This further allows teams to maintain high-quality standards while keeping production speeds up.

With its ability to adapt, connect, and optimize, AI is enabling manufacturers and supply chains to move from rigid and reactive systems to intelligent and resilient operations. Let’s further check some major areas in manufacturing where AI is playing an important role.

Key AI Use Cases Driving Results: AI in Manufacturing

AI is no longer a distant promise for manufacturers. It’s already being used on factory floors and across supply chains to solve everyday challenges, from keeping machines running to improving product quality and planning production more accurately. Here are some of the most practical applications making a real difference today:

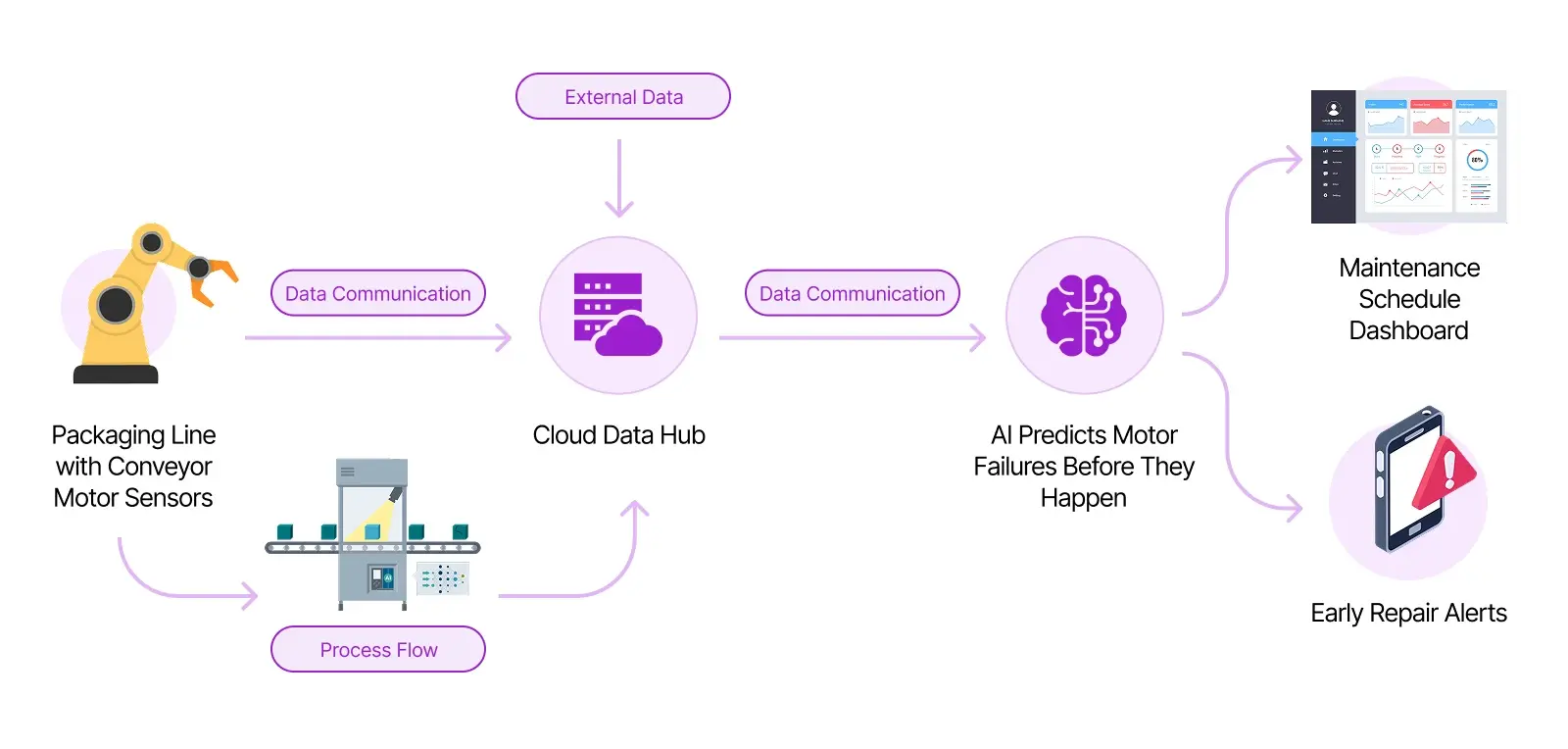

1. Predictive Maintenance

AI systems analyze sensor and machine data to forecast when equipment is likely to fail, thus allowing maintenance teams to intervene before costly breakdowns occur. This not only reduces downtime but also extends machinery lifespan.

Example: A packaging plant uses AI to monitor conveyor motor performance, scheduling repairs days before a failure would halt production.

2. Quality Inspection with Computer Vision

AI-driven vision systems detect defects in real time with higher accuracy than human inspection, even for subtle or new defect types. This not only improves quality but also reduces costly rework and recalls.

Example: An electronics manufacturer catches micro-cracks in circuit boards that traditional inspection tools miss, which reduces rework costs.

3. Supply Chain Forecasting & Demand Planning

Machine learning models process historical data, market trends, and external factors to fine-tune inventory and production schedules. McKinsey reports AI-driven forecasting can reduce errors by 20–50% and cut lost sales or product unavailability by up to 65%.

Example: An apparel brand aligns production with seasonal demand shifts. Thus, further avoids costly overstock or stockouts.

4. Robotics & Cobots in Production

AI-powered robots and collaborative bots (cobots) handle repetitive, heavy, or accuracy tasks alongside human operators. This improves worker safety and ensures consistent throughput.

Example: In an automotive assembly line, cobots handle accurate welding while workers focus on complex assembly tasks.

5. Digital Twin & Real-Time Process Optimization

Digital twins create virtual replicas of production lines or entire supply chains, enabling manufacturers to simulate changes, test “what-if” scenarios, and optimize processes before making physical adjustments. Combined with AI, they allow real-time parameter adjustments for peak efficiency.

Example: A food manufacturer uses a digital twin to simulate cooking processes and ingredient variations, automatically adjusting times and temperatures to maintain consistent taste and texture.

6. Generative AI for Design & Knowledge Transfer

Generative AI is emerging as a powerful tool to accelerate product design, streamline production documentation, and enhance workforce training. By automating knowledge transfer and creating design variations quickly, it shortens time-to-market and reduces onboarding times for workers.

Example: A machinery manufacturer uses generative AI to produce multiple prototype designs in days instead of weeks, significantly speeding up development cycles.

Interested to learn more about AI use cases in manufacturing? Read in detail here!

In short, AI in manufacturing isn’t just automation; it’s augmentation. Each use case pairs human expertise with AI’s ability to process vast amounts of data and act in real time, creating operations that are smarter, faster, and more adaptable.

AI in Manufacturing: How AI Turns Possibility into Performance?

Moving from AI experiments to enterprise-wide transformation takes more than just the right technology; it requires strategy, governance, and disciplined execution. The manufacturers, seeing the biggest returns, tend to follow a few common principles:

1. Start with High-Value, Measurable Use Cases

Instead of trying to use AI everywhere at once, successful teams start with one or two applications that clearly provide ROI- like predictive maintenance or demand forecasting. These early wins help build trust and make it easier to expand AI across the business.

2. Build on Strong Data Foundations

AI’s accuracy depends on the quality and accessibility of data. That’s why leading companies focus on cleaning and connecting their data, often creating shared platforms that bring together information from production, supply chain, and business systems.

3. Layer Governance and Security from Day One

AI in manufacturing touches critical operations and sensitive data. Effective governance frameworks define who can access data, how models are monitored, and how results are validated. This not only mitigates risk but also accelerates compliance with industry regulations.

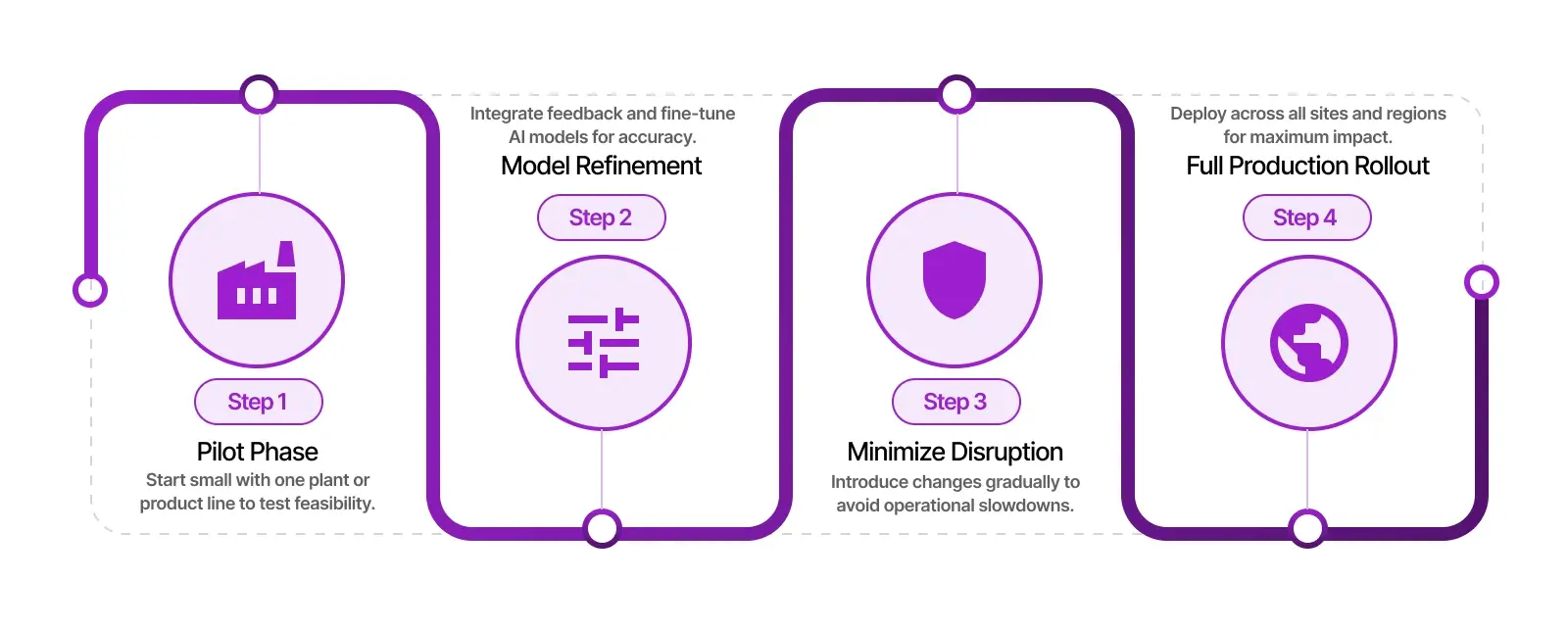

4. Scale Through Phased Implementation

Deploying AI in stages, from pilot to production, allows teams to refine models, integrate feedback, and minimize disruption. Many manufacturers start in a single plant or product line before expanding to multiple sites and regions.

5. Blend Human Expertise with AI

AI isn’t here to replace operators, planners, or engineers; it’s here to support them. By capturing expert knowledge in models and keeping people involved in important decisions, companies get the best of both worlds: human experience and AI-driven efficiency.

When executed with the right approach, AI shifts from an “innovation experiment” to a performance engine. Hence, reducing downtime, strengthening supply chain management, and accelerating decision-making at every level of manufacturing.

And these points aren’t just theory; manufacturers worldwide are already turning them into measurable results. Let’s know more about it.

Real-World Wins: Company Success Stories for AI in Manufacturing & Supply Chain

Here are a few examples of how leading companies are translating AI’s potential into performance:

1. Dow – Boosting Yield and Throughput

Chemical giant Dow has embedded AI into its production processes to fine-tune variables like temperature, pressure, and material flow. By analyzing thousands of process parameters in real time, Dow has improved yield and increased throughput, thus translating into higher output without additional capital investment.

2. Toro – Smarter Tariff and Inventory Management

Outdoor equipment maker Toro uses AI to navigate complex tariff rules and optimize just-in-time inventory. By combining supply chain data with predictive analytics, Toro can handle shifts in demand, adjust sourcing strategies, and keep production humming without costly overstock or shortages.

Industry-Wide Wins

Across sectors, manufacturers are applying AI to accelerate product design, reduce quality defects, and build supply chains resilient to disruption. Whether it’s a food producer cutting waste through AI-backed demand forecasts or an automotive supplier detecting defects with computer vision. The lesson is clear – when applied well, AI helps businesses move faster, waste less, and stay competitive.

Challenges Manufacturers Face – and How to Overcome Them

AI in manufacturing holds enormous promise, but realizing that promise means overcoming some very real hurdles. From tangled legacy systems to workforce readiness, here’s a look at the biggest challenges and practical ways to address them.

1. Data Integrity and Readiness

Many manufacturers still face issues with separate systems, inconsistent data collection, and outdated infrastructure. Without high-quality, unified data, even the smartest AI models can produce unreliable results.

How to overcome it: Begin with a comprehensive data readiness audit. Modernize your data infrastructure, integrate disparate sources, and implement governance standards to ensure consistency. Tools like automated quality checks, real-time dashboards, and data cataloging can accelerate progress.

Markovate’s approach: We design AI-powered manufacturing solutions only after ensuring the underlying data foundation is robust, enabling reliable predictions, smarter automation, and faster ROI.

2. Legacy System Integration

Older on-premises or custom-built systems often don’t “speak the same language” as modern AI platforms, thus creating interoperability issues.

How to overcome it: Prioritize open standards, modular architectures, and interoperability when selecting AI platforms. Develop integration roadmaps that allow gradual adoption without operational disruption. Markovate specializes in bridging legacy manufacturing systems with next-gen AI capabilities, ensuring a seamless transition.

3. Data Privacy, Security, and Compliance

Manufacturing data often contains sensitive IP and operational details. With evolving regulations on AI ethics and privacy, security is non-negotiable.

How to overcome it: Use edge computing to process sensitive data locally, enforce encryption at every stage, and conduct regular security audits. Consider federated learning to train AI without centralizing sensitive information. Markovate builds AI models with security-by-design principles, thus ensuring compliance with industry and regulatory standards.

4. Scaling Beyond Pilot Projects

Many AI initiatives stall after the proof-of-concept stage, either due to technical constraints or unclear ROI.

How to overcome it: Start with high-impact, measurable use cases, define clear KPIs, and expand iteratively. Maintain control over your training data and build internal expertise to avoid vendor lock-in. Markovate’s phased deployment framework helps manufacturers move from pilot to full-scale rollout while steadily increasing ROI.

The challenges are real, but they are not roadblocks. With the right strategy, strong governance, and expert partners, AI can move from “interesting pilot” to a fully embedded driver of operational excellence. Markovate’s end-to-end manufacturing AI development expertise ensures every stage – from data preparation to scaling – is set up for measurable success.

Markovate’s Proven Expertise in AI for Manufacturing

When manufacturers are ready to move beyond pilot testing and truly scale AI, Markovate brings the strategic vision and technical backbone needed to turn possibilities into hard performance gains.

For manufacturers, this means faster pilots, measurable ROI within months, and seamless integration with existing systems – without disruption.

Why Markovate Stands Out?

- End-to-end AI expertise: From strategy and consulting to deployment, monitoring, and MLOps, Markovate supports every phase of the AI lifecycle.

- Manufacturing-specific skill set: Whether it’s building AI digital twins, detection systems, manufacturing agents, or optimizing inventory and production workflows, our solutions are customized to the realities of production environments.

- Rapid, measurable delivery: We deploy custom AI solutions – from pilot to live – within weeks, not years, ensuring faster realization of ROI.

Our Work Example: AI-Powered Safety Monitoring & SIF Prevention

We teamed up with a major manufacturing client to transform workplace safety using AI. Here’s what we achieved together:

-

24/7 hazard detection

via real-time monitoring of worker behavior, PPE compliance, and proximity to risky equipment, powered by edge-enabled vision and sensor fusion.

-

Risk analytics and proactive insight

AI-generated hotspots and predictive risk scoring helped safety managers deploy resources smarter and faster.

Results that speak volumes

- Recordable injuries dropped by 78%

- PPE compliance improved from 70% to 98% within just three months

- A 3× ROI on the safety investment in the first year alone.

Scaling Beyond the Factory Floor With Markovate

This same AI foundation – fast data capture, predictive analytics, and edge intelligence – applies equally well to supply chain optimization.

By extending AI capabilities from the shop floor to inventory management, logistics, and supplier coordination, manufacturers can achieve synchronized production schedules, reduce excess stock, and minimize costly delays – delivering end-to-end efficiency across the supply chain.

What’s Ahead? The Future of AI in Manufacturing & Supply Chains

AI is shifting from an operational tool to a strategic driver, powering smarter factories and more adaptive supply chains. The next wave will be shaped by Generative AI in manufacturing for rapid product design, edge-to-cloud systems for real-time decision-making, and resilient AI agents that respond instantly to disturbances.

We will see mass customization become mainstream, like BMW’s build-to-order model, alongside greener, tech-enabled supply chains using blockchain, automation, and predictive analytics. Hyper-connected logistics, from autonomous vehicles to drone deliveries, will push just-in-time production to new heights.

The takeaway: AI isn’t just about keeping pace; it’s about setting the pace. The manufacturers who start building now will own the future.

The future is already in motion. The question isn’t if AI will transform your manufacturing and supply chain operations; it’s how soon you will capture the competitive advantage. Start small, scale fast, and partner with experts like Markovate who can turn AI’s promise into measurable business performance.

So, are you ready to unlock measurable ROI from AI in manufacturing?

Markovate helps global manufacturers move from pilot to scale in weeks, not years. Let’s start a conversation.

FAQs

1. How does AI improve efficiency in manufacturing and supply chains?

AI improves efficiency by doing the heavy lifting on data and repetitive tasks. It can predict equipment issues before breakdowns, spot defects faster than the human eye, and fine-tune supply chain planning with greater accuracy. For manufacturers, this means fewer delays, reduced waste, and smarter use of resources; all adding up to faster and more reliable operations.

2. What are some real applications of AI in manufacturing and supply chains?

It powers demand forecasting to plan inventory better, improves quality control by spotting defects instantly, and enables predictive maintenance to prevent costly downtime. It also supports route optimization for faster deliveries, inventory management to avoid overstock or shortages, and even supplier selection to strengthen sourcing decisions.

3. What are the key features of AI in manufacturing and supply chains?

AI helps manufacturers in several ways: it personalizes products to customer needs, scales easily with demand or market changes, and drives smarter decisions with data insights. It also automates routine tasks and provides real-time guidance to workers.